Zeol Rotor Concentrator VOC Abatement System

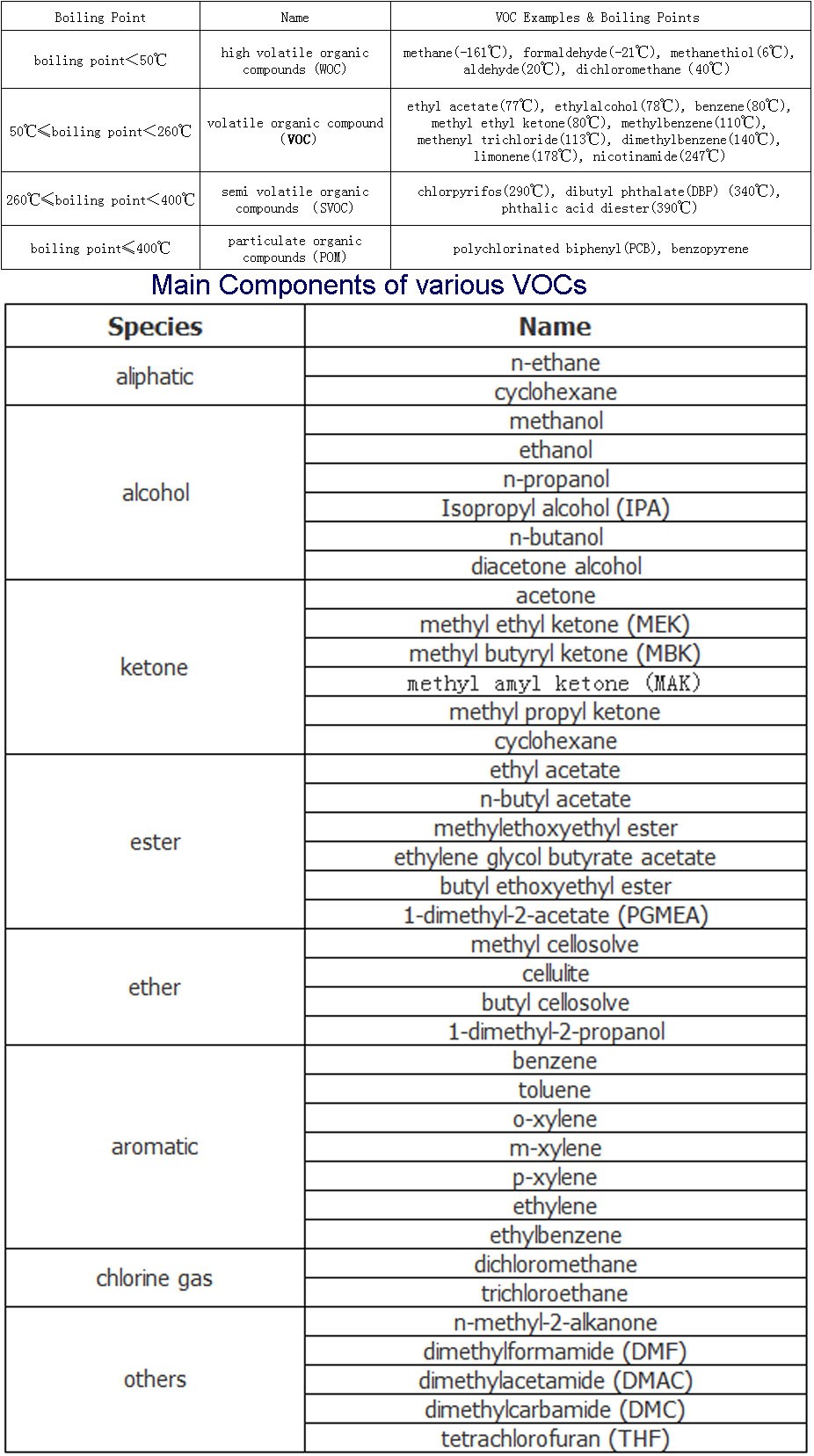

VOC Classification

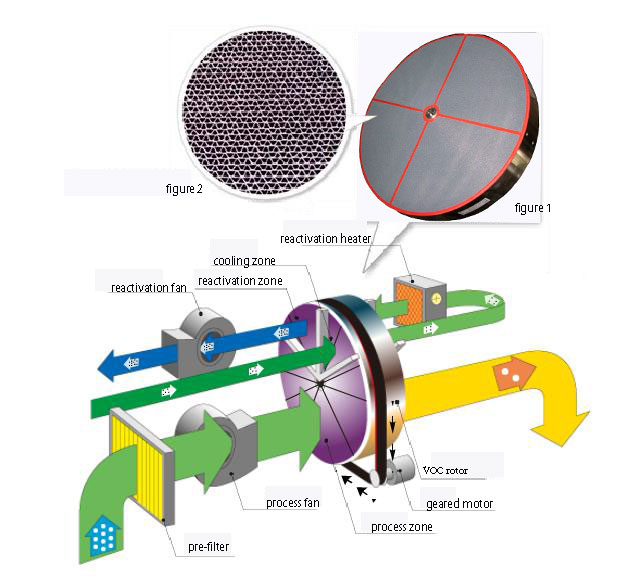

VOCs Rotor

The VOCs rotor is a high capacity desiccant media captivated in a perimeter band with radial spokes. The spokes attach to a central hub with integral sealed ball bearings. The sealed bearings ride on a solid center shaft with spacer plates attached to the cassette structure with shoulder screws.

Main Sizes of VOCs Rotor

| Diameter mm | Depth mm | Shaft Diameter mm | Delivered Knock-down | |||

| 650 - 1050 |

|

|

|

|||

|

|

30 | Can | |||

| 2200 - 5000 |

|

40 | Yes |

Hodream VOCs Rotor has the below Features

1. high competence and reliability.

2. CNC fabricated unit and have powder coated finishing

3. hard face finish on rotor`s edge ensures long life.

4. coating helps good sealing for media and seals.

5. appropriate for electrical, steam, thermal fluid.

6. rotor frame complete set at perimeter for industrial quality and durability.

7. rotor is non-flammable.

8. comfortable to all major components.

9. durable for continuous hassle free operation.

10. easy serviceability and operation without any maintenance.

11. water washable, and are quick and easy to service.

12. made of alternate flat and corrugated inorganic fiber of very uniform pitch and height.

13. available in non-standard sizes

14. Honeycomb cell height: 1.8-3.4mm, low height can Increased absorption area

Application of VOCs Rotor Concentrator

(1) organic waste concentrated wheel. For separating the solvent from the exhaust gas containing organic solvent is widely used in paint waste gas pre-treatment, the organic solvent recovered from the exhaust gas containing high-boiling organic solvent and the solvent containing the odor control plant

(2) concentrated ammonia runner. Treatment of waste gas containing low concentrations of ammonia, ammonia utilization achieved

(3) hydrogen sulfide concentrate runner. For the treatment of organic fertilizer foul odor produced by fermentation and drying process. The company can concentrate rotor according to the user's need to develop a variety of purposes sieve

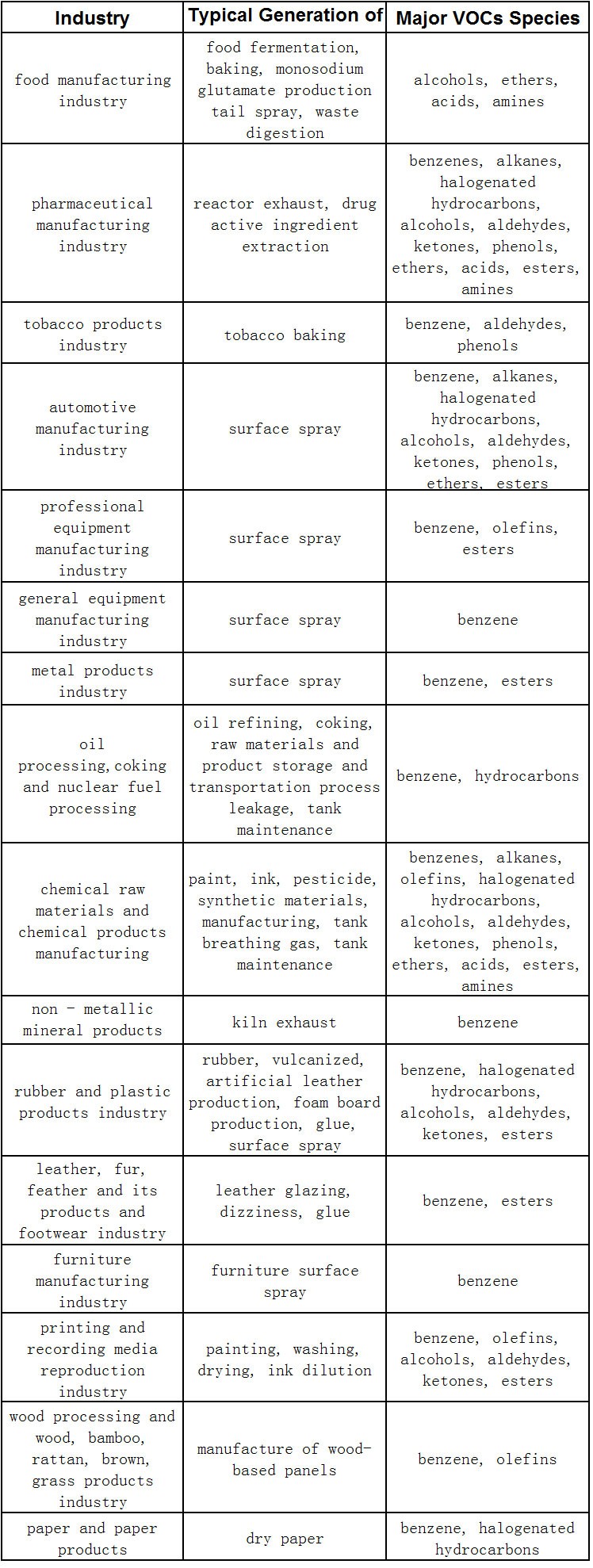

Working principle of VOCs concentrated runner

Runner honeycomb structure, see on Figure 2. Runner adsorbent material can be adsorbed hydrophobic organic solvent molecular sieves . Wheel is divided into three regions namely treatment area , the cooling zone and regeneration zone , in a motor driven wheel rotation, rotation speed of 1-12 rev / hour

Solvent -containing gas into a relatively clean air flow from the area after the treatment , the organic solvent content can be reduced to a minimum the following 50mg/m3 , meet the national environmental emissions requirements. Part of the air contained in the organic solvent from the regenerative effect of the fan after the stream cooling zone is heated to the regeneration heater 180 ℃, then through the regeneration zone of the rotor . When the regeneration air flows through the rotor , the rotor of the adsorbed organic solvent is desorbed at high temperature , while the regeneration air is taken away . When turning work , the regeneration air and process air ratio is between 1 / 3 to 1 / 10 , the regeneration of the organic solvent

Honeycomb cell height: 1.8-3.4mm, low height can Increased absorption area

VOCs Rotor can be used at Zeolite Rotor Concentrator, RTO (RCO) exhaust gas treatment device

Package of VOCs Rotor