silica gel or molecular sieve desiccant rotor for industrial dehumidfifier

Desiccant Rotor

The desiccant rotor is a high capacity desiccant media captivated in a perimeter band with radial spokes. The spokes attach to a central hub with integral sealed ball bearings. The sealed bearings ride on a solid center shaft with spacer plates attached to the cassette structure with shoulder screws.

Hodream Silica Gel Desiccant Rotor Properties

Materia Composition: Hodream silica gel desiccant rotor has a very high 82% acttive silica gel content and only 15% glass fibre content, the remaining 3% is the acrylic surface coating.

Technical Propertise: there is no limit for how high relative humidity the rotor can stand as long as droplets are not introduced into the rotor during operation. The Hodream rotor can be washed in water with weak non-alkaline detergent, after saturation in humid air.

Physical Properties: the density of dry material is approx 300kgs/cubic meter. The Hodream media can pick up approx. 39.5% of it’s dry weight as moisture in humid environment. The surface compression strength of the rotor is more than 200Kpa.

|

Diameter mm |

Depth mm |

Shaft Diameter mm |

Delivered Knock-down |

|

500 - 600 |

50, 100, 200 |

20 |

No. |

|

650 - 1050 |

100, 200, 400 |

20 |

No. |

|

1150 - 2000 |

200, 400 |

30 |

Can |

|

2200 - 5000 |

200, 400 |

40 |

Yes |

We can produce rotor size according to customer’s request.

special small silica gel desiccant rotor for household dehumidifier

|

Diameter mm |

Depth mm |

Shaft Diameter mm |

Delivered Knock-down |

|

190 - 400 |

30, 50, 100 |

0-20 |

No. |

We can produce rotor size according to customer’s request.

Hodream Molecular Sieve Desiccant Rotor (Desiccant Molsieve Rotor) Properties

Materia Composition: Hodream molecular sieve desiccant rotor has a very high 38% molecular sieve content, 45% acttive silica gel content and only 15% glass fibre content, the remaining 2% is the acrylic surface coating.

Technical Propertise: there is no limit for how high relative humidity the rotor can stand as long as droplets are not introduced into the rotor during operation. The Hodream rotor can be washed in water with weak non-alkaline detergent, after saturation in humid air.

Physical Properties: the density of dry material is approx 310kgs/cubic meter. The Hodream media is designed to have its maximum capacity at low moisture content in the air or when the entering air is hot. The surface compression strength of the rotor is more than 200Kpa.

|

Diameter mm |

Depth mm |

Shaft Diameter mm |

Delivered Knock-down |

|

500 - 600 |

50, 100, 200 |

20 |

No. |

|

650 - 1050 |

100, 200, 400 |

20 |

No. |

|

1150 - 2000 |

200, 400 |

30 |

Can |

|

2200 - 5000 |

200, 400 |

40 |

Yes |

We can produce rotor size according to customer’s request.

Hodream Silica Gel Desiccant Rotor and Molecular Sieve Desiccant Rotor have the below Features

1. high competence and reliability.

2. CNC fabricated unit and have powder coated finishing

3. hard face finish on rotor`s edge ensures long life.

4. coating helps good sealing for media and seals.

5. appropriate for electrical, steam, thermal fluid.

6. excellent moisture removal capacity at relatively economical energy.

7. rotor frame complete set at perimeter for industrial quality and durability.

8. rotor is non-flammable.

9. comfortable to all major components.

10. durable for continuous hassle free operation.

11. easy serviceability and operation without any maintenance.

12. water washable, and are quick and easy to service.

13. made of alternate flat and corrugated inorganic fiber of very uniform pitch and height.

14. available in non-standard sizes

15. Honeycomb cell height: 1.8-3.4mm, low height can Increased absorption area

Application of Desiccant Rotor Dehumidifier

. Schools, universities, dormitories;

. Offices, condominiums, apartments;

. Smoking lounges, casinos;

. Hospitals, nursing homes, day care centers;

. Hotels, motels, department stores;

. Clean rooms, circuit board, chip manufacturing;

. Breweries;

. Swimming pools, sports arenas;

. Convention centers, airports, prisons;

. Bus and train maintenance facilities;

. Welding, foundry, casting areas;

. Printing operations;

. All humidity controlled spaces; and

. Product drying operations.

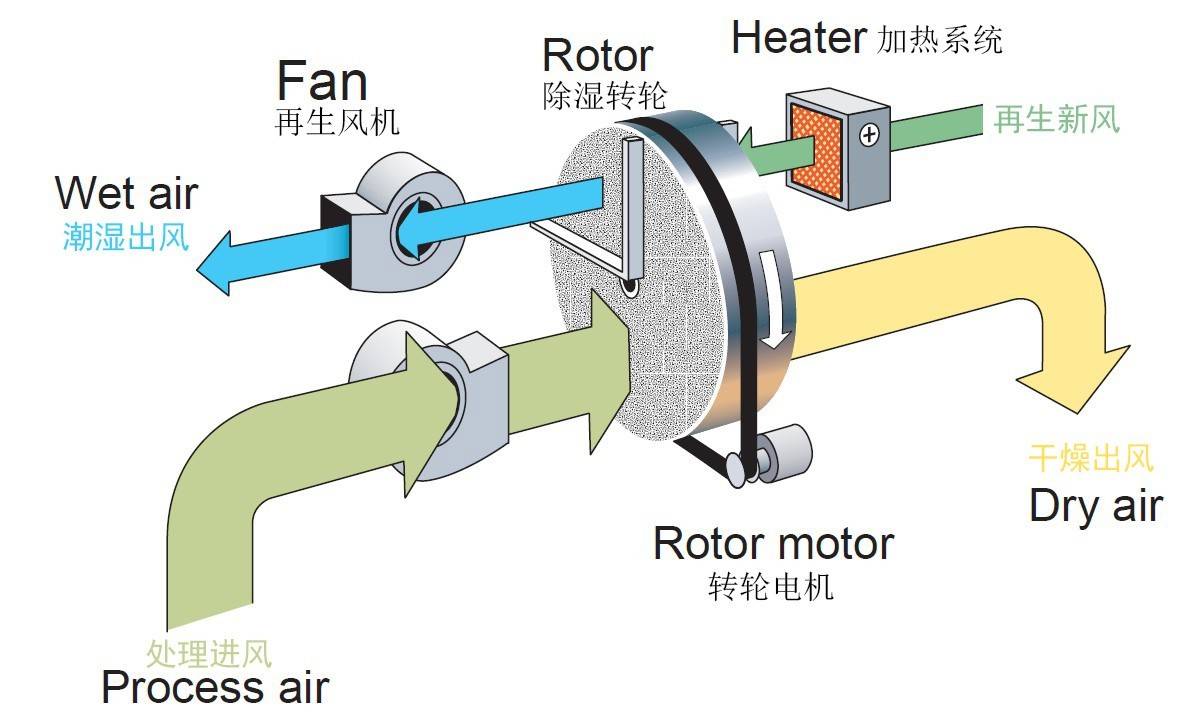

Operation Diagram of Desiccant Rotor Dehumidifier (Unit)

Desiccant Rotor can be used at Dehumidifier or Dehumidifier Unit

Package of Desiccant Rotor